Basic characteristics of high-pressure resin hoses

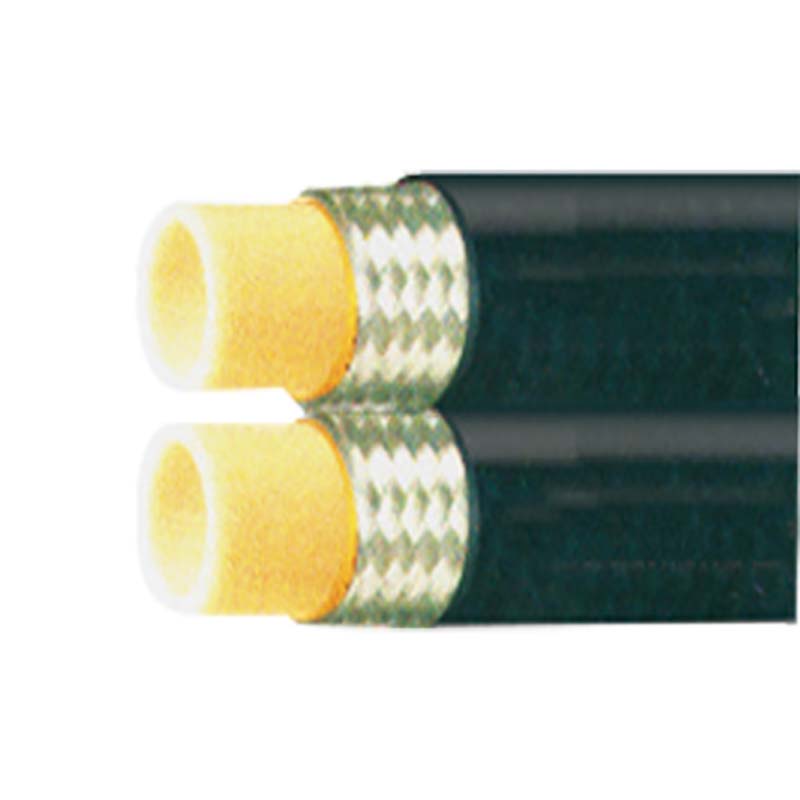

The steel wire braided high-pressure resin hose is made of wear-resistant and high tensile synthetic rubber or special synthetic resin, and the outer layer is made of high-strength steel wire braided. This design greatly improves the working pressure and wear resistance of the hose. Usually, these types of hoses can withstand pressures of up to several hundred pascals and can work stably in complex environments.

material structure

The inner layer of the hose is usually made of synthetic rubber with excellent oil resistance, such as nitrile rubber (NBR) or fluororubber (FKM), which provides the hose with good heat resistance and chemical stability. The function of outer steel wire weaving is to enhance strength and wear resistance, making it suitable for long-term use under high pressure, high temperature, and harsh environments. This multi-layer structure design not only provides excellent durability for hoses when transporting liquids, but also effectively prevents hydraulic oil leakage.

Process processing

The production process of each steel wire braided high-pressure resin hose undergoes strict process control to ensure its excellent performance. The key steps in the production process include material selection, process control, and final testing. During the weaving process, it is necessary to ensure the uniform distribution and tight bonding of the steel wires to prevent deformation or breakage of the hose due to external compression during use. In addition, the mixture of resin and rubber also needs to be strictly controlled for uniformity to ensure the flexibility and tensile strength of the hose.

Application areas and their advantages

In various applications of hydraulic oil transportation, steel wire braided high-pressure resin hoses have demonstrated their irreplaceable superiority. It is widely used in fields such as engineering machinery, petroleum drilling equipment, mining machinery, and shipping equipment. Here are a few advantages in its application process:

High voltage bearing capacity

In high-pressure hydraulic systems, due to the high-pressure thrust of the oil, hoses must be able to withstand enormous internal and external pressures. The design of steel wire weaving ensures the high-pressure bearing capacity of the hose, which can adapt to the requirements of high-power equipment without problems such as pipe expansion and rupture.

Wear resistant and corrosion-resistant

Wear resistance and corrosion resistance are important considerations in the process of transporting petroleum based hydraulic oil. High pressure resin hoses have excellent oil and chemical resistance, which can effectively resist the corrosion of hydraulic oil and other chemicals, extending their service life.

Excellent flexibility

Despite having high strength, high-pressure resin hoses still maintain excellent flexibility. This means that it can be easily used in complex pipeline layouts without installation difficulties due to high hardness. In addition, this flexibility also makes the hose more elastic and earthquake resistant during operation, effectively improving the stability of the system.

High temperature resistance characteristics

In high-temperature working environments, ordinary hoses may lose their elasticity or even burst due to thermal expansion. The material properties of steel wire braided high-pressure resin hoses endow them with excellent high-temperature resistance, making them suitable for use in harsh high-temperature environments without deformation or performance degradation due to temperature effects.

Importance in industrial applications

In modern industrial applications, high-pressure resin hoses have become an important component to ensure the normal operation of equipment. Its quality and performance directly affect the safety and efficiency of production equipment and the entire system:

Application in construction machinery

Construction machinery requires frequent changes in construction positions and operating conditions during the construction process, which places high demands on the flexibility and adaptability of hydraulic systems. High pressure resin hoses, due to their high strength and flexibility, can meet the needs of hydraulic equipment under high loads and dynamic conditions, providing a guarantee for the efficient operation of construction machinery.

Application in mining equipment

Mining equipment usually faces extremely harsh working conditions, and hoses face many challenges such as mining dust, impact, and high temperature. Therefore, steel wire braided high-pressure resin hoses with wear resistance and high pressure resistance have become the ideal choice for hydraulic systems in mining machinery. The wear-resistant characteristics both inside and outside ensure that the hose can maintain excellent performance in long-term harsh environments.

Application in oil drilling equipment

The working state of oil drilling equipment is extremely complex, often requiring continuous operation in harsh environments such as high pressure, high temperature, and heavy pollution. High pressure resin hoses, with their excellent pressure bearing capacity and chemical stability, can effectively solve the problems in hydraulic oil transportation, improve the overall stability and work efficiency of drilling equipment.

epilogue

As an indispensable part of hydraulic systems, steel wire braided high-pressure resin hoses have become the preferred choice for industrial and mechanical equipment applications due to their excellent pressure bearing capacity, wear resistance, and enormous flexibility. This article only provides a brief analysis of its structure, application, and advantages. In the future, more optimization solutions need to be explored in industrial environments to provide support for the integration and development of emerging and traditional industries.

Basic characteristics of high-pressure resin hoses

The steel wire braided high-pressure resin hose is made of wear-resistant and high tensile synthetic rubber or special synthetic resin, and the outer layer is made of high-strength steel wire braided. This design greatly improves the working pressure and wear resistance of the hose. Usually, these types of hoses can withstand pressures of up to several hundred pascals and can work stably in complex environments.

material structure

The inner layer of the hose is usually made of synthetic rubber with excellent oil resistance, such as nitrile rubber (NBR) or fluororubber (FKM), which provides the hose with good heat resistance and chemical stability. The function of outer steel wire weaving is to enhance strength and wear resistance, making it suitable for long-term use under high pressure, high temperature, and harsh environments. This multi-layer structure design not only provides excellent durability for hoses when transporting liquids, but also effectively prevents hydraulic oil leakage.

Process processing

The production process of each steel wire braided high-pressure resin hose undergoes strict process control to ensure its excellent performance. The key steps in the production process include material selection, process control, and final testing. During the weaving process, it is necessary to ensure the uniform distribution and tight bonding of the steel wires to prevent deformation or breakage of the hose due to external compression during use. In addition, the mixture of resin and rubber also needs to be strictly controlled for uniformity to ensure the flexibility and tensile strength of the hose.

Application areas and their advantages

In various applications of hydraulic oil transportation, steel wire braided high-pressure resin hoses have demonstrated their irreplaceable superiority. It is widely used in fields such as engineering machinery, petroleum drilling equipment, mining machinery, and shipping equipment. Here are a few advantages in its application process:

High voltage bearing capacity

In high-pressure hydraulic systems, due to the high-pressure thrust of the oil, hoses must be able to withstand enormous internal and external pressures. The design of steel wire weaving ensures the high-pressure bearing capacity of the hose, which can adapt to the requirements of high-power equipment without problems such as pipe expansion and rupture.

Wear resistant and corrosion-resistant

Wear resistance and corrosion resistance are important considerations in the process of transporting petroleum based hydraulic oil. High pressure resin hoses have excellent oil and chemical resistance, which can effectively resist the corrosion of hydraulic oil and other chemicals, extending their service life.

Excellent flexibility

Despite having high strength, high-pressure resin hoses still maintain excellent flexibility. This means that it can be easily used in complex pipeline layouts without installation difficulties due to high hardness. In addition, this flexibility also makes the hose more elastic and earthquake resistant during operation, effectively improving the stability of the system.

High temperature resistance characteristics

In high-temperature working environments, ordinary hoses may lose their elasticity or even burst due to thermal expansion. The material properties of steel wire braided high-pressure resin hoses endow them with excellent high-temperature resistance, making them suitable for use in harsh high-temperature environments without deformation or performance degradation due to temperature effects.

Importance in industrial applications

In modern industrial applications, high-pressure resin hoses have become an important component to ensure the normal operation of equipment. Its quality and performance directly affect the safety and efficiency of production equipment and the entire system:

Application in construction machinery

Construction machinery requires frequent changes in construction positions and operating conditions during the construction process, which places high demands on the flexibility and adaptability of hydraulic systems. High pressure resin hoses, due to their high strength and flexibility, can meet the needs of hydraulic equipment under high loads and dynamic conditions, providing a guarantee for the efficient operation of construction machinery.

Application in mining equipment

Mining equipment usually faces extremely harsh working conditions, and hoses face many challenges such as mining dust, impact, and high temperature. Therefore, steel wire braided high-pressure resin hoses with wear resistance and high pressure resistance have become the ideal choice for hydraulic systems in mining machinery. The wear-resistant characteristics both inside and outside ensure that the hose can maintain excellent performance in long-term harsh environments.

Application in oil drilling equipment

The working state of oil drilling equipment is extremely complex, often requiring continuous operation in harsh environments such as high pressure, high temperature, and heavy pollution. High pressure resin hoses, with their excellent pressure bearing capacity and chemical stability, can effectively solve the problems in hydraulic oil transportation, improve the overall stability and work efficiency of drilling equipment.

epilogue

As an indispensable part of hydraulic systems, steel wire braided high-pressure resin hoses have become the preferred choice for industrial and mechanical equipment applications due to their excellent pressure bearing capacity, wear resistance, and enormous flexibility. This article only provides a brief analysis of its structure, application, and advantages. In the future, more optimization solutions need to be explored in industrial environments to provide support for the integration and development of emerging and traditional industries.

Online Message

Please fill in your name and message, and don't forget to email and/or call if you wish. We will reply within 24 hours.