In today's rapidly developing technological world, the importance of flexible conveying systems cannot be underestimated. API hoses are one of the multifunctional pipeline solutions that play an important role in industries, agriculture, petrochemicals, and other fields. For those who wish to understand its meaning and purpose, this article will explore in detail all aspects of API hoses. By gaining a deep understanding of the characteristics and application scenarios of this pipeline, you will be able to make informed decisions when making a choice.

What is API hose?

API stands for American Petroleum Institute, which is an organization that develops standards for the oil and gas industry. API hoses are therefore named, mainly referring to hoses that meet the standards of the organization. These hoses have undergone rigorous testing and validation to ensure their excellent performance in various harsh environments.

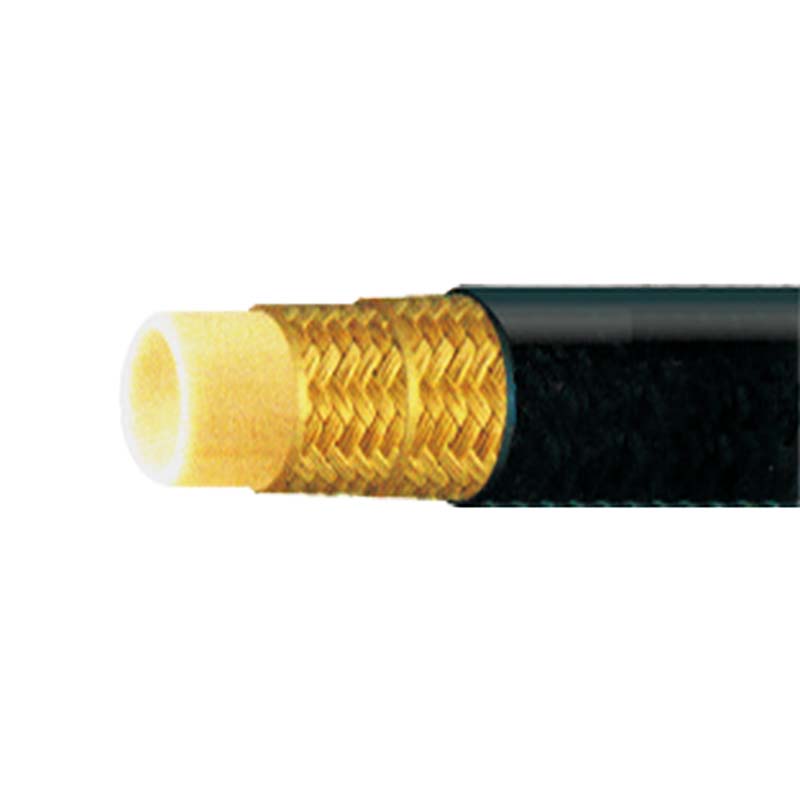

API hoses are typically composed of multiple layers of materials, including inner lining, reinforcement layer, and outer layer. The inner lining is usually made of corrosion-resistant materials such as polytetrafluoroethylene (PTFE), while the reinforcement layer uses woven metal or synthetic fibers to increase the strength of the pipeline. The outermost layer provides protection and is usually made of wear-resistant and weather resistant materials. These constituent materials ensure the high durability and reliability of API hoses, which are widely used in various applications that require elasticity and robustness.

Application scope of API hoses

Due to their superior properties such as high temperature resistance, high pressure resistance, and corrosion resistance, API hoses are widely used in multiple fields.

1. Oil and gas industry

In the process of oil drilling and transportation, the requirements for equipment and materials are extremely strict. API hoses are commonly used for oil and gas transmission and processing due to their outstanding corrosion resistance and high pressure resistance. The hose can remain stable under high pressure, avoiding leakage and ensuring the safety and efficiency of work. In addition, API hoses also have good wear resistance and are suitable for use in harsh drilling environments.

2. Chemical industry

The chemical industry needs to handle various highly corrosive liquids, so corrosion-resistant materials are the key to its equipment. The PTFE lining of API hoses provides excellent chemical stability and can safely transport various corrosive chemicals, such as strong acids, alkaline solutions, etc. Through this approach, API hoses demonstrate significant advantages in ensuring process safety and stable operation.

3. Food and pharmaceutical industry

These industries have strict requirements for hygiene and safety standards, and the design of API hoses allows them to be used for the transportation of sensitive fluids. Due to its lining material meeting food grade standards, API hoses can safely transport dairy products, drinking water, and pharmaceuticals. The antibacterial properties and easy to clean design make it an ideal choice for fluid transport in sanitary environments.

4. Marine and Ship Applications

API hoses are used in fuel transportation, sewage treatment, and ballast water systems in the marine and marine industries. Good resistance to salt spray and climate aging enables them to overcome the harshness of marine environments and ensure long-term trouble free operation.

Choose the appropriate API hose

1. Select based on fluid and pressure rating

The selection of hoses should be based on the type of fluid they are intended to transport and the pressure they may withstand in the system. High pressure environments require specially designed high-strength API hoses, which will determine the inner diameter and wall thickness of the hoses.

2. Temperature resistance is crucial

API hoses typically need to operate at different temperatures, so when selecting, their temperature resistance range should be fully considered. Choosing hoses that exceed the actual operating temperature range will greatly improve safety and equipment lifespan.

3. Pay attention to the flexibility and durability of hoses

Flexibility has a significant impact on the installation and maintenance of equipment, and an ideal API hose should have both good flexibility and durability. The high-quality reinforcement layer provides the necessary strength for the hose while ensuring its reliability during use.

4. Chemical resistance

Select appropriate lining materials based on the chemical properties of the transportation medium to ensure that the hose can be exposed to chemical environments for a long time without damage.

Maintenance and upkeep of API hoses

Although API hoses are well-designed, they still require regular maintenance to ensure their optimal performance and service life. The usual maintenance measures include regular inspection of the hose for visible signs of wear and leakage, and cleaning and maintenance according to the manufacturer's recommendations. These measures can detect potential problems early and fix them in a timely manner, avoiding greater losses.

summary

API hoses play a crucial role in modern industry, providing reliable solutions for multiple industries with their high efficiency and durability. Understanding its structure and functional characteristics can help users choose suitable products based on specific needs. In addition, good maintenance and upkeep will ensure the long-term use of hoses, protecting equipment and the environment. Through the guidance in this article, we hope you can better understand and use API hoses to improve your production efficiency and equipment safety.