In the vast field of industrial production and energy transmission, high-pressure steam pipes and steam high-pressure pipes play an indispensable role in transmitting power and heat. They not only carry high-temperature and high-pressure steam, but also directly relate to the stability, efficiency, and safety of the entire system. This article will start from the basic concepts of high-pressure steam pipes and steam high-pressure pipes, and deeply explore their design principles, material selection, manufacturing processes, application fields, maintenance, and future development trends, in order to provide comprehensive and in-depth insights for practitioners and researchers in related fields.

1、 Basic concepts and classifications

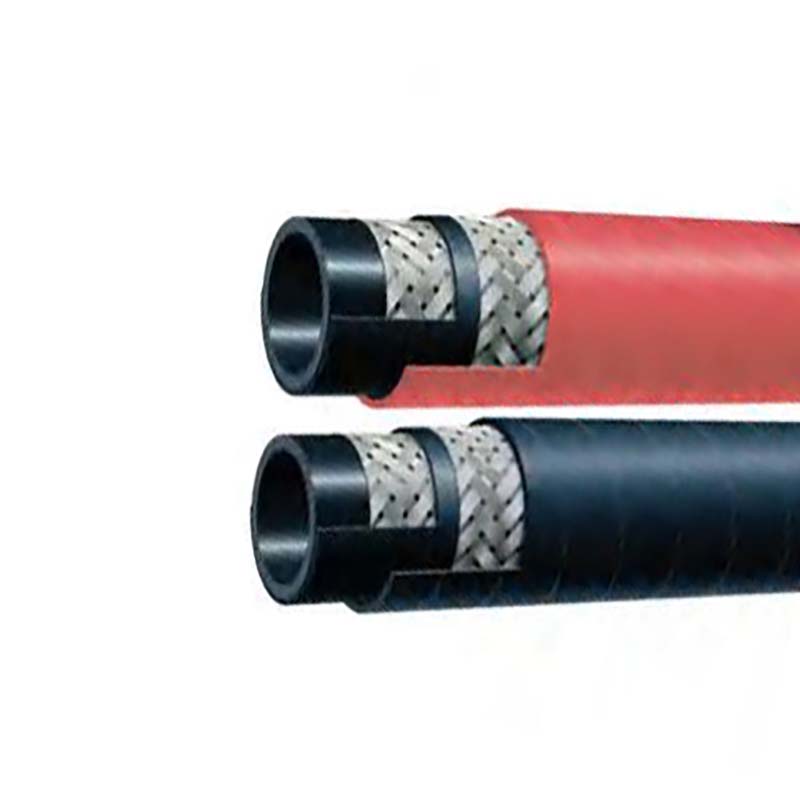

High pressure steam pipe, as the name suggests, is a piping system used to transport high-pressure steam. And the steam high-pressure pipe emphasizes more on its ability to withstand high-pressure steam and its application under specific working conditions. According to different purposes, pressure levels, materials, and connection methods, high-pressure steam pipes and steam high-pressure pipes can be divided into various types, such as seamless steel pipes, welded steel pipes, cast iron pipes, composite pipes, etc. Each type has its unique advantages and application scenarios, such as seamless steel pipes, which are widely used in industries such as power and chemical due to their high strength and good pressure bearing capacity; Composite pipes, with their excellent corrosion resistance and lightweight characteristics, have shown broad application prospects in fields such as marine engineering and petrochemicals.

2、 Design principles and material selection

The design of high-pressure steam pipes and steam high-pressure pipes must strictly follow relevant standards and specifications to ensure that they can operate safely and stably in high temperature and high pressure environments while meeting production needs. In the design process, it is necessary to comprehensively consider factors such as the working pressure, temperature, medium properties, flow rate, installation conditions, and environmental factors of the pipeline, and determine key parameters such as wall thickness, diameter, material, and support hanger settings of the pipeline through calculation.

Material selection is one of the core elements in the design of high-pressure steam pipes and steam high-pressure pipes. High quality pipes can not only effectively resist corrosion, fatigue, and creep under high temperature and pressure, but also improve the overall performance and service life of the system. At present, commonly used pipes include low-alloy high-strength steel, stainless steel, heat-resistant alloy steel, etc. These materials not only have excellent mechanical properties and thermal stability, but also meet the corrosion resistance requirements under specific working conditions.

3、 Manufacturing process and quality control

The manufacturing process of high-pressure steam pipes and steam high-pressure pipes is complex and precise, involving multiple stages such as raw material inspection, cutting, forming, welding, heat treatment, non-destructive testing, and anti-corrosion treatment. Each stage requires strict quality control to ensure the performance and safety of the final product.

In the welding process, advanced welding techniques and equipment such as automatic welding, argon arc welding, etc. are used to improve welding quality and efficiency. At the same time, strict visual inspection, radiographic testing, or ultrasonic testing should be conducted on the welds to ensure that there are no defects such as cracks or slag inclusions. Heat treatment is an important step in improving the performance of pipes. Through a reasonable heat treatment process, welding stress can be eliminated, tissue properties can be improved, and the toughness and corrosion resistance of pipes can be enhanced.

4、 Application Fields and Case Analysis

High pressure steam pipes and steam high-pressure pipes are widely used in various industries such as power, chemical, petroleum, metallurgy, textile, papermaking, etc. In the power industry, as key components such as the main steam pipeline and reheat steam pipeline of power plants, they undertake the important task of transporting high-temperature and high-pressure steam to the turbine for power generation; In the chemical industry, it is used for steam transmission and heating cooling circulation systems between various reaction vessels and distillation towers.

5、 Maintenance and Safety Management

The maintenance and upkeep of high-pressure steam pipes are key to ensuring their long-term safe operation. Regular pipeline inspections, cleaning of scale, and replacement of aging components can promptly identify and eliminate potential safety hazards. At the same time, strengthening the safety training and management of operators, improving emergency response capabilities, is also an important means to ensure the safety of pipeline systems.

In terms of safety management, a sound pipeline safety management system and emergency response plan system should be established. By conducting regular drills and training, we aim to enhance the safety awareness and emergency response capabilities of all employees. In addition, strengthen communication and coordination with other departments and units, form a linkage mechanism, and jointly respond to possible emergencies.

6、 Future Development Trends

With the advancement of technology and the development of industry, high-pressure steam pipes and steam high-pressure pipes will face more challenges and opportunities. On the one hand, with the continuous emergence of new materials and the continuous innovation of manufacturing processes, the performance and safety of pipeline systems will be further improved; On the other hand, with the adjustment of energy structure and the improvement of environmental protection requirements, higher requirements have been put forward for the energy conservation, consumption reduction, and environmental performance of pipeline systems.

In the future, high-pressure steam pipes and steam high-pressure pipes will develop towards higher pressure levels, larger diameters, longer lifespans, lower energy consumption, and better environmental performance. Meanwhile, with the popularization and application of intelligent and digital technologies, the monitoring, control, and maintenance of pipeline systems will become more convenient and efficient. This will bring safer, more efficient, and environmentally friendly steam transmission solutions to industrial production.