Choosing the appropriate oil hose: the difference between 16C and 7K

In the modern oil and gas extraction industry, oil hoses play a crucial role. The correct flexible pipeline is not only related to the safety and efficiency of the project, but also directly affects the cost of the operation. Among numerous models, 16C petroleum hoses and 7K petroleum hoses are widely used due to their excellent performance. This article will delve into the characteristics, application areas, and how to choose suitable hoses for these two types of petroleum hoses, in order to help companies and construction personnel make informed decisions.

Overview of petroleum hoses

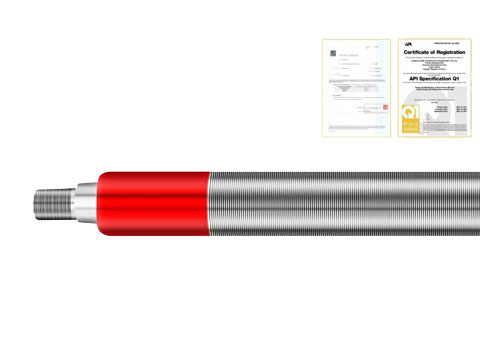

Petroleum hose, as the name suggests, is a flexible pipeline used for transporting petroleum and related liquids. There are various specifications and models of petroleum hoses depending on their usage and working environment. When choosing a hose, multiple factors need to be considered, including working temperature, pressure, properties of the conveying medium, wear resistance, etc. Due to the chemical properties of petroleum and its derivatives, the selected hose must have good oil resistance and corrosion resistance.

Characteristics of 16C petroleum hose

1. Design standards

The 16C oil hose follows the 16C standard, which is an internationally recognized high-pressure hose standard suitable for operation in the oil and gas industry. This standard specifies the requirements for the structure, materials, testing, and labeling of hoses to ensure their safety and reliability in high-pressure environments.

2. Materials

16C hoses are usually made of high-quality synthetic rubber or polyurethane materials, which can effectively resist oil, wear, and have good elasticity and tensile strength. In addition, the 16C hose is often equipped with a steel wire braided reinforcement layer to improve its resistance to pressure and torsion.

3. Scope of application

16C petroleum hoses are mainly used in petroleum exploration, drilling, pumping, and oil and gas transportation. Its high pressure resistance and wear-resistant materials enable it to work in extreme environments and are widely used in onshore and offshore oil fields.

4. Work pressure and temperature

The working pressure of a 16C hose can generally reach 20MPa, and higher-level hoses can even reach higher pressure standards. Its working temperature range is wide, usually from -20 ℃ to+100 ℃, which meets the needs of most oil and gas operations.

Characteristics of 7K petroleum hoses

1. Design standards

The 7K oil hose follows the 7K standard and is mainly used in the marine drilling and oil transportation industries. The 7K standard aims to ensure safety under high pressure, high temperature, and harsh environments. Its design requirements are extremely strict, including specific regulations on hose interfaces, pressure resistance levels, and materials.

2. Materials

7K hoses are usually made of composite materials, with an inner layer of oil resistant rubber, a middle layer of steel wire or synthetic fiber reinforcement, and an outer layer of wear-resistant shell. This composite design ensures its stable performance under high-strength tension and compression.

3. Scope of application

7K petroleum hoses are mainly used in fields such as deep well drilling, marine operations, and pipeline transportation. Its excellent compressive and high-temperature resistance enables it to maintain good working conditions even in extreme environments.

4. Work pressure and temperature

The working pressure of 7K hoses can usually reach 30MPa, and they are designed to withstand temperatures ranging from -30 ℃ to+120 ℃, providing strong support for operations in offshore and extreme environments.

Comparison between 16C and 7K hoses

Although both types of petroleum hoses are used for transporting fluids such as petroleum, there are significant differences in design standards, materials, application areas, and performance parameters.

1. Work pressure and temperature differences

The 16C hose is more suitable for medium and low pressure operations, while the 7K hose can withstand higher working pressures and temperatures. This makes the 7K hose more adaptable in extreme environments and more suitable for deep well and offshore drilling operations.

2. Differences in materials and structures

Although both are made of composite materials, the 7K hose has higher performance parameters in terms of specific material composition and structural design, especially in terms of compression and wear resistance. On the one hand, this enables the 7K hose to maintain stable performance even under long-term and high-intensity working conditions.

3. Differences in application fields

The 16C hose is mainly used for onshore oil field operations, while the 7K hose is more commonly used for marine operations and deep well drilling. Therefore, if your project is carried out offshore, choosing 7K oil hoses would be more suitable.

How to choose a suitable oil hose

Choosing the appropriate oil hose is crucial for ensuring engineering safety and efficiency. Here are some key factors to consider when choosing oil hoses:

1. Working environment

The first thing to consider is the type of working environment, including temperature, pressure, and the presence of corrosive media. These factors directly affect the selection of hoses.

2. Transport medium

Different conveying media have different requirements for hoses. For example, oil and gas media require hoses to have good oil resistance, while chemical liquids require corrosion resistance.

3. Budget

Reasonably select hoses based on the project budget, as different models and brands of hoses may have price differences. The ideal choice is to find a balance between performance, security, and cost.

4. Certification and Standards

Ensure that the selected hoses comply with relevant industry standards and certifications to ensure their reliability and safety during operation.

5. Supplier reputation

Choosing a reputable supplier can ensure high-quality products and excellent after-sales service. Understanding the reputation and history of suppliers can help reduce risks.

summary

When choosing oil hoses, the models of 16C and 7K each have their own application scenarios and performance characteristics. Understanding the differences between these two types of hoses can help engineers and construction workers make reasonable choices based on their needs in practical operations, ensuring the safety and efficiency of the project. Whether it is a 16C petroleum hose or a 7K petroleum hose, comprehensive considerations should be made from multiple aspects such as working environment, conveying medium, budget, and supplier reputation to select the most suitable product and ensure the smooth progress of oil and gas operations.

Choosing the appropriate oil hose: the difference between 16C and 7K

In the modern oil and gas extraction industry, oil hoses play a crucial role. The correct flexible pipeline is not only related to the safety and efficiency of the project, but also directly affects the cost of the operation. Among numerous models, 16C petroleum hoses and 7K petroleum hoses are widely used due to their excellent performance. This article will delve into the characteristics, application areas, and how to choose suitable hoses for these two types of petroleum hoses, in order to help companies and construction personnel make informed decisions.

Overview of petroleum hoses

Petroleum hose, as the name suggests, is a flexible pipeline used for transporting petroleum and related liquids. There are various specifications and models of petroleum hoses depending on their usage and working environment. When choosing a hose, multiple factors need to be considered, including working temperature, pressure, properties of the conveying medium, wear resistance, etc. Due to the chemical properties of petroleum and its derivatives, the selected hose must have good oil resistance and corrosion resistance.

Characteristics of 16C petroleum hose

1. Design standards

The 16C oil hose follows the 16C standard, which is an internationally recognized high-pressure hose standard suitable for operation in the oil and gas industry. This standard specifies the requirements for the structure, materials, testing, and labeling of hoses to ensure their safety and reliability in high-pressure environments.

2. Materials

16C hoses are usually made of high-quality synthetic rubber or polyurethane materials, which can effectively resist oil, wear, and have good elasticity and tensile strength. In addition, the 16C hose is often equipped with a steel wire braided reinforcement layer to improve its resistance to pressure and torsion.

3. Scope of application

16C petroleum hoses are mainly used in petroleum exploration, drilling, pumping, and oil and gas transportation. Its high pressure resistance and wear-resistant materials enable it to work in extreme environments and are widely used in onshore and offshore oil fields.

4. Work pressure and temperature

The working pressure of a 16C hose can generally reach 20MPa, and higher-level hoses can even reach higher pressure standards. Its working temperature range is wide, usually from -20 ℃ to+100 ℃, which meets the needs of most oil and gas operations.

Characteristics of 7K petroleum hoses

1. Design standards

The 7K oil hose follows the 7K standard and is mainly used in the marine drilling and oil transportation industries. The 7K standard aims to ensure safety under high pressure, high temperature, and harsh environments. Its design requirements are extremely strict, including specific regulations on hose interfaces, pressure resistance levels, and materials.

2. Materials

7K hoses are usually made of composite materials, with an inner layer of oil resistant rubber, a middle layer of steel wire or synthetic fiber reinforcement, and an outer layer of wear-resistant shell. This composite design ensures its stable performance under high-strength tension and compression.

3. Scope of application

7K petroleum hoses are mainly used in fields such as deep well drilling, marine operations, and pipeline transportation. Its excellent compressive and high-temperature resistance enables it to maintain good working conditions even in extreme environments.

4. Work pressure and temperature

The working pressure of 7K hoses can usually reach 30MPa, and they are designed to withstand temperatures ranging from -30 ℃ to+120 ℃, providing strong support for operations in offshore and extreme environments.

Comparison between 16C and 7K hoses

Although both types of petroleum hoses are used for transporting fluids such as petroleum, there are significant differences in design standards, materials, application areas, and performance parameters.

1. Work pressure and temperature differences

The 16C hose is more suitable for medium and low pressure operations, while the 7K hose can withstand higher working pressures and temperatures. This makes the 7K hose more adaptable in extreme environments and more suitable for deep well and offshore drilling operations.

2. Differences in materials and structures

Although both are made of composite materials, the 7K hose has higher performance parameters in terms of specific material composition and structural design, especially in terms of compression and wear resistance. On the one hand, this enables the 7K hose to maintain stable performance even under long-term and high-intensity working conditions.

3. Differences in application fields

The 16C hose is mainly used for onshore oil field operations, while the 7K hose is more commonly used for marine operations and deep well drilling. Therefore, if your project is carried out offshore, choosing 7K oil hoses would be more suitable.

How to choose a suitable oil hose

Choosing the appropriate oil hose is crucial for ensuring engineering safety and efficiency. Here are some key factors to consider when choosing oil hoses:

1. Working environment

The first thing to consider is the type of working environment, including temperature, pressure, and the presence of corrosive media. These factors directly affect the selection of hoses.

2. Transport medium

Different conveying media have different requirements for hoses. For example, oil and gas media require hoses to have good oil resistance, while chemical liquids require corrosion resistance.

3. Budget

Reasonably select hoses based on the project budget, as different models and brands of hoses may have price differences. The ideal choice is to find a balance between performance, security, and cost.

4. Certification and Standards

Ensure that the selected hoses comply with relevant industry standards and certifications to ensure their reliability and safety during operation.

5. Supplier reputation

Choosing a reputable supplier can ensure high-quality products and excellent after-sales service. Understanding the reputation and history of suppliers can help reduce risks.

summary

When choosing oil hoses, the models of 16C and 7K each have their own application scenarios and performance characteristics. Understanding the differences between these two types of hoses can help engineers and construction workers make reasonable choices based on their needs in practical operations, ensuring the safety and efficiency of the project. Whether it is a 16C petroleum hose or a 7K petroleum hose, comprehensive considerations should be made from multiple aspects such as working environment, conveying medium, budget, and supplier reputation to select the most suitable product and ensure the smooth progress of oil and gas operations.

Online Message

Please fill in your name and message, and don't forget to email and/or call if you wish. We will reply within 24 hours.