In the fields of ocean engineering, port maintenance, shipbuilding, and industrial cleaning, high-pressure cleaning hoses and rust removal hoses for ships play an essential role as indispensable tools. They are not only efficient cleaning and rust removal tools, but also key factors in ensuring job safety and improving work efficiency. This article will delve into the technical characteristics, application scenarios, maintenance, and future development trends of these two types of hoses, in order to provide comprehensive and in-depth guidance for practitioners in related industries.

Technical Characteristics Analysis

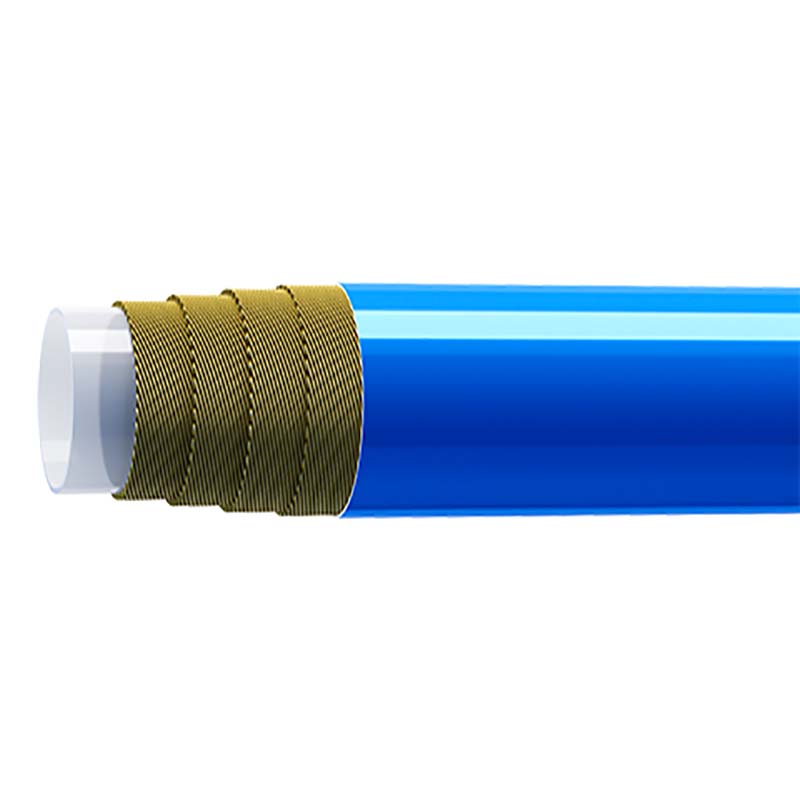

Ship high-pressure cleaning hose: This type of hose is designed to withstand high-pressure water flow and is usually made of high-strength synthetic rubber or polyurethane material, lined with wear-resistant and corrosion-resistant steel wire or polyester fiber layers to ensure stability and durability under extreme working conditions. Its unique structural design can effectively resist the impact of high-pressure water flow, while maintaining good flexibility and bending radius, making it easy to operate flexibly in narrow spaces. In addition, high-pressure cleaning hoses also need to have good sealing performance to prevent water leakage and ensure cleaning efficiency and safety.

Rust removal high-pressure hose: Similar to high-pressure cleaning hoses, rust removal high-pressure hoses also need to withstand high-pressure impacts, but their material selection is more stringent to deal with corrosive substances such as metal debris and chemicals that may be encountered during the rust removal process. Therefore, this type of hose often uses a special alloy steel wire braided reinforcement layer, covered with wear-resistant and corrosion-resistant synthetic rubber or special plastic to ensure long-term service life in harsh environments. The rust removal high-pressure hose also needs to have excellent spraying effect. Through precise design of nozzle shape and spraying angle, efficient and uniform rust removal effect can be achieved, reducing damage to the substrate.

Overview of Application Scenarios

Ship maintenance: In the daily maintenance of ships, high-pressure cleaning hoses are used to clean marine organisms, oil stains, and old paint layers attached to the surface of the hull, restore the smoothness of the hull, reduce navigation resistance, and improve fuel efficiency. The rust removal high-pressure hose is specifically used to treat corroded areas on the hull and deck, preparing for subsequent anti-corrosion coating construction and extending the service life of the ship.

Port facilities: Port facilities such as docks, piers, breakwaters, etc. are exposed to seawater and air for a long time and are susceptible to erosion and corrosion. High pressure cleaning hoses and rust removal hoses play an important role in such situations, helping to clean dirt, restore the surface condition of facilities, and ensure the safe operation of ports.

Industrial cleaning: In industries such as petroleum, chemical, and steel, high-pressure cleaning hoses and rust removal hoses are widely used in equipment cleaning, pipeline dredging, tank rust removal, and other operations to improve production efficiency and reduce maintenance costs.