The performance and reliability of air pipeline systems are crucial in high temperature, high pressure, and oil environments, especially in industrial manufacturing, petrochemicals, aerospace, and other fields. Among them, high-temperature oil resistant braided steel wire air pipes, as a pipeline component designed specifically for extreme working conditions, have gradually become the preferred solution in the industry due to their excellent heat resistance, oil resistance, and high-strength structural characteristics. This article will delve into the structural design, material selection, manufacturing process, performance characteristics, and application cases of high-temperature oil resistant braided steel wire air pipes, aiming to provide readers with comprehensive and in-depth professional knowledge.

1、 Structural Design and Material Selection

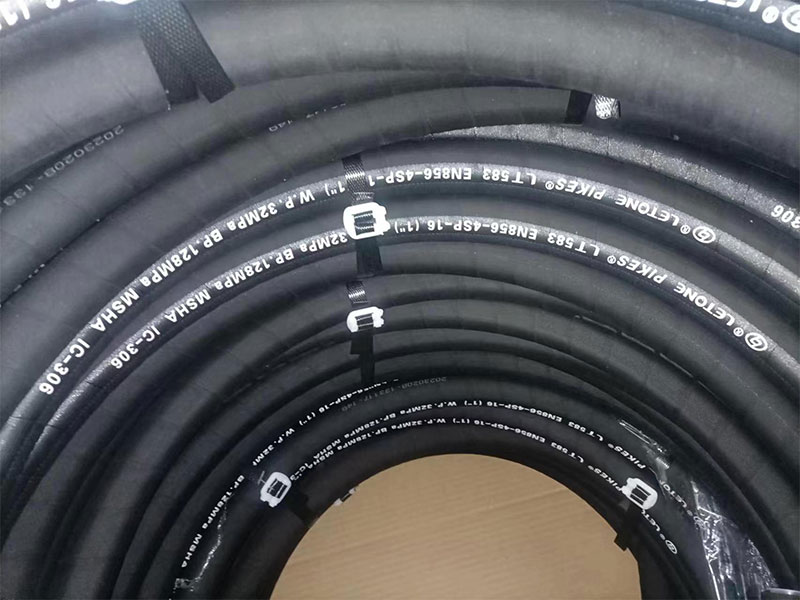

The core of high-temperature oil resistant braided steel wire air pipe lies in its unique structural design, which usually consists of three parts: inner pipe body, braided reinforcement layer, and outer cover layer. The inner tube body is often made of synthetic rubber or special plastic materials that are resistant to high temperature and oil corrosion, such as fluororubber, nitrile rubber, or polytetrafluoroethylene (PTFE). These materials can maintain excellent sealing and chemical resistance in high temperature environments. The woven reinforcement layer is made of high-strength stainless steel wire or alloy steel wire, and a mesh structure is formed through precision weaving technology, greatly improving the pressure resistance and impact resistance of the pipeline. The outer coating further enhances the wear resistance, aging resistance and external environment adaptability of the pipeline, and rubber or polyurethane materials with good weather resistance are often selected.

2、 Manufacturing process

The manufacturing process of high-temperature oil resistant woven steel wire air pipes involves multiple complex processes such as precision extrusion, weaving and winding, vulcanization and cross-linking. Firstly, the inner tube material is uniformly extruded into shape using precision extrusion equipment; Subsequently, an automated weaving machine is used to tightly weave stainless steel wire or alloy steel wire at a specific angle and density outside the inner tube body, forming a sturdy reinforcement layer; Finally, the outer layer is coated or wrapped with outer coating material, and through high-temperature vulcanization crosslinking process, the layers are tightly bonded to form an air duct with excellent overall performance. The entire manufacturing process requires strict control of parameters such as temperature, pressure, and speed to ensure stable and reliable product quality.

3、 Performance characteristics

1. High temperature resistance: The inner and outer layers made of high temperature resistant materials, as well as the stainless steel braided reinforcement layer, enable the pipeline to operate stably for a long time in high temperature environments up to several hundred degrees, meeting the needs of extreme working conditions.

2. Oil corrosion resistance: The inner layer material has excellent corrosion resistance to various oils, effectively preventing oil penetration and erosion, ensuring the cleanliness of the pipeline interior, and extending its service life.

3. High strength and pressure resistance: The woven reinforcement layer endows the pipeline with extremely high tensile strength and pressure resistance, which can maintain structural stability even in high-pressure environments and is not easily broken or deformed.

4. Good flexibility and bendability: The unique weaving structure gives the pipeline good flexibility and bendability, making it easy to install and adapt to complex pipeline layouts.

5. Wear resistance and anti-aging: the selection and design of the outer coating materials enable the pipeline to have excellent wear resistance and anti-aging performance, which can be used for a long time in harsh environments without being easily damaged.

4、 Application Cases

High temperature and oil resistant braided steel wire air pipes are widely used in various occasions that require high temperature, high pressure, and oil corrosion resistance. In the petrochemical industry, it is used to transport high-temperature oil and gas media, connect various reaction vessels, storage tanks, and process equipment; In the aerospace field, due to its lightweight, high strength, and high temperature resistance, it is used in aircraft hydraulic systems and fuel systems; In addition, it is widely used in industries such as metallurgy, power, and automobile manufacturing, such as ventilation systems for high-temperature furnaces and engine cooling systems.

With the advancement of technology and the development of industry, the requirements for high-temperature and oil resistant braided steel wire air pipes will become increasingly high. In the future, research in this field will focus more on material innovation and application, such as developing higher performance high-temperature and oil resistant materials to enhance the high-temperature and oil corrosion resistance of pipelines; Meanwhile, the optimization of manufacturing processes and the improvement of intelligence level will also become important development directions to enhance production efficiency and product quality. In addition, with the increasing awareness of environmental protection, the application of green and environmentally friendly materials will also become a research hotspot, promoting the development of high-temperature oil resistant braided steel wire air pipes towards a more environmentally friendly and sustainable direction.

In summary, high-temperature oil resistant braided steel wire air pipes play an increasingly important role in modern industry due to their excellent performance and wide application prospects. With the continuous advancement of technology and the expansion of the market, we believe that it will demonstrate its unique value and charm in more fields.