In the field of modern architecture and engineering, concrete is one of the most common building materials, and its transportation process often becomes a key link in determining the progress and quality of the project. Traditional concrete conveying methods, such as using metal pipes, although to some extent meet construction needs, still have shortcomings in terms of wear resistance, portability, and flexibility. In recent years, with the advancement of materials science, a new type of material - UPE (ultra high molecular weight polyethylene) ultra wear-resistant concrete conveying hose has gradually emerged, bringing revolutionary changes to the field of concrete conveying with its unique performance advantages.

1、 Material characteristics of UPE ultra wear-resistant concrete conveying hose

UPE, Ultra high molecular weight polyethylene is a polymer with a molecular weight exceeding one million. Due to its extremely long molecular chains and high intermolecular forces, it has extremely high wear resistance, impact resistance, and corrosion resistance. Compared with traditional metal pipelines, UPE ultra wear-resistant concrete conveying hoses can significantly reduce wear caused by friction and collision during concrete conveying, thereby greatly extending their service life.

In addition, UPE materials also have good flexibility and elasticity, allowing hoses to adapt to various complex construction environments and terrain conditions during transportation, ensuring the continuity and stability of concrete transportation. At the same time, UPE materials also have excellent cold and heat resistance, which can maintain stable performance under extreme temperature conditions.

2、 Structural design of UPE ultra wear-resistant concrete conveying hose

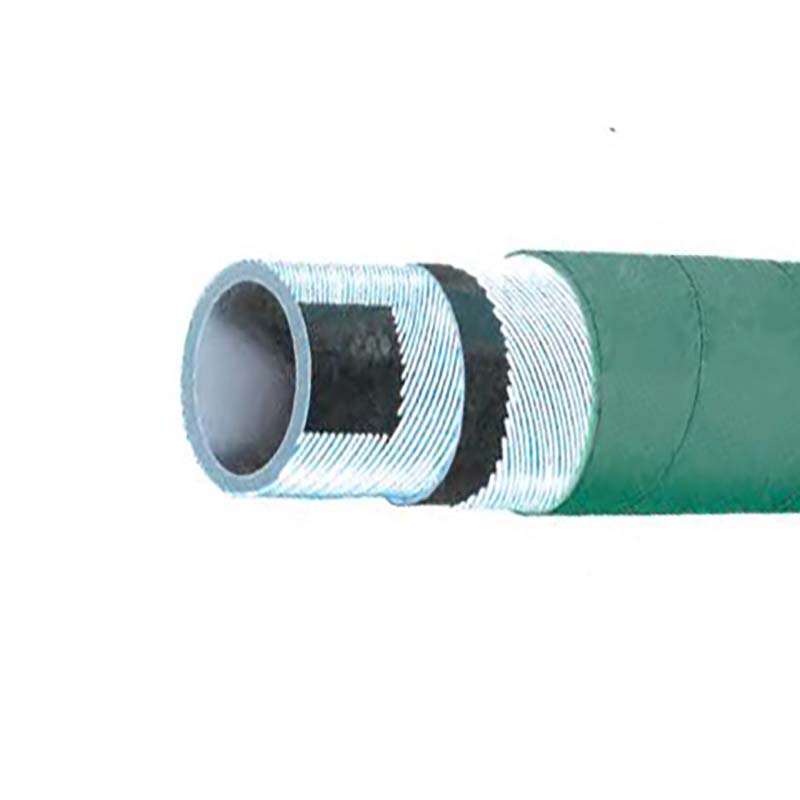

The UPE ultra wear-resistant concrete conveying hose adopts a multi-layer structure design, including the inner layer, reinforcement layer, and outer layer. The inner layer is made of UPE material, responsible for direct contact with concrete and bearing wear and tear; The reinforcement layer uses high-strength fiber materials to enhance the tensile strength and pressure resistance of the hose; The outer layer is made of wear-resistant and corrosion-resistant materials, which protect the inner layer and enhance the layer.

This multi-layer structure design enables UPE ultra wear-resistant concrete conveying hoses to have excellent wear resistance, as well as high compressive and tensile strength. In addition, the hose is equipped with dedicated connectors and seals to ensure that there is no leakage or leakage during the transportation process.

3、 Application advantages of UPE ultra wear-resistant concrete conveying hose

1. Improve construction efficiency: Due to the excellent wear resistance and flexibility of UPE ultra wear-resistant concrete conveying hoses, they can adapt to various complex construction environments and terrain conditions, greatly reducing downtime and maintenance costs during the construction process, and improving construction efficiency.

2. Reduce construction costs: Compared with traditional metal pipelines, UPE ultra wear-resistant concrete conveying hoses have a longer service life and lower maintenance costs. In addition, hoses also have the characteristics of being lightweight and easy to handle, which can greatly reduce logistics costs during the construction process.

3. Environmental Protection and Energy Conservation: The UPE ultra wear-resistant concrete conveying hose is made of environmentally friendly materials, which will not cause harm to the environment and human health. Meanwhile, due to its excellent wear resistance, it can reduce the discharge of waste and pollutants generated by wear, achieving green construction.

4. High safety: UPE ultra wear-resistant concrete conveying hose has excellent compressive and tensile strength, which can ensure that there will be no leakage and leakage during the conveying process, thereby ensuring the safety and stability of construction.

4、 Future prospects of UPE ultra wear-resistant concrete conveying hoses

With the continuous development of materials science and engineering technology, UPE ultra wear-resistant concrete conveying hoses will have broader application prospects in the future. On the one hand, with the continuous emergence of new materials and technologies, the performance of UPE materials will be further improved, giving hoses higher performance advantages in wear resistance, corrosion resistance, and flexibility; On the other hand, with the continuous innovation and progress of construction technology, UPE ultra wear-resistant concrete conveying hoses will be able to better adapt to various complex construction environments and terrain conditions, making greater contributions to the development of the construction and engineering fields.