In multiple industries such as chemistry, healthcare, and aerospace, the performance requirements for materials are becoming increasingly stringent. Especially in the field of fluid transportation, a material is needed that can resist various corrosive media while maintaining stable performance in extreme environments. PTFE rubber hoses stand out in these fields due to their unique performance and become an indispensable "universal conveyor".

2、 Overview of PTFE rubber hoses

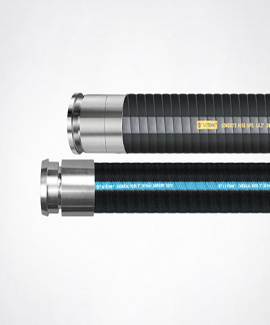

PTFE rubber hose, also known as polytetrafluoroethylene rubber hose, is a special pipe made of polytetrafluoroethylene (PTFE) material. PTFE, commonly known as the "plastic king", is a polymer material with excellent chemical resistance, high temperature resistance, low friction coefficient, and insulation performance. PTFE rubber hoses are made through precise processing technology, inheriting the excellent properties of PTFE materials and possessing a series of eye-catching characteristics.

3、 Performance characteristics of PTFE rubber hoses

Stable chemical performance: PTFE rubber hoses are almost unaffected by any chemical substances and can safely and reliably transport corrosive media such as acids, alkalis, and salts. This characteristic has made it widely used in industries such as chemical, petroleum, and natural gas.

Excellent resistance to high and low temperatures: PTFE rubber hoses can maintain flexibility at extremely low temperatures, while also maintaining stable performance in high temperature environments. It has a high temperature resistance of 260 ℃ and can be used in low temperature environments of -250 ℃ without embrittlement or aging.

Strong wear resistance: The inner wall of PTFE rubber hose is very smooth, with low friction coefficient, which can effectively protect the conveying medium and reduce conveying resistance. This makes it perform well in various fluid transport and wear environments.

Good explosion-proof performance: PTFE rubber hoses have good explosion-proof performance, and when conveying flammable and explosive media, they will not generate electric sparks to cause explosions, with high safety.

Long service life: Due to its excellent chemical properties, high and low temperature resistance, as well as strong wear resistance, PTFE rubber hoses have a longer service life, reducing replacement frequency and maintenance costs.

4、 Application fields of PTFE rubber hoses

Chemical industry: PTFE rubber hoses are widely used in the chemical industry, such as conveying corrosive media such as acids, alkalis, salts, and as sealing materials in various chemical reaction devices.

Oil and Gas Industry: In the oil and gas industry, PTFE rubber hoses are used to transport high-pressure media such as oil and liquid petroleum gas, and can maintain stable performance under harsh environmental conditions.

Pharmaceutical industry: Due to its excellent chemical properties, high and low temperature resistance, as well as strong wear resistance, PTFE rubber hoses are widely used in the pharmaceutical industry, such as transporting drugs and cleaning equipment.

Medical industry: PTFE rubber hoses are also used in the medical field due to their good biocompatibility and low toxicity, such as manufacturing medical devices such as artificial blood vessels and heart valves.

Aerospace industry: PTFE rubber hoses are also used in the aerospace industry, such as manufacturing seals, bearings, lubricating materials, etc. for aircraft engines.

5、 Conclusion

PTFE rubber hoses have become an indispensable "universal conveyor" in multiple industries due to their excellent performance and wide application scenarios. With the continuous development of technology, the application fields of PTFE rubber hoses will be further expanded, contributing greater strength to the development of various industries.